IBR approved API 5L X52 PSL2 Steel LSAW Pipe Exporter, 3LPP Coated API 5L X52 LSAW Pipe, API 5L Grade X52 PSL1 LSAW Pipes, API 5L L360 LSAW Pipe Stockists, Carbon steel API 5L X52 LSAW Pipe Supplier, API 5L X52 FBE Coated LSAW Pipes in Mumbai, India.

3LPE Coating API 5L X52 LSAW Pipe, API 5L X52 Longitudinally Submerged Arc Welded Pipes Dealers in Mumbai, Black Steel API 5L X52 LSAW Pipe Distributors in India, API 5L X52 Longitudinal LSAW Pipes Stockholders, API 5L L360 Carbon Steel LSAW Line Pipe Traders.

Table of Content

API 5L X52 LSAW Pipe- information about the pipe for buyers

API 5L X52 LSAW Pipes Specifications

API 5L L360 LSAW Pipe Chemical Composition

API 5L Gr X52 LSAW Pipes Mechanical Properties

API 5L X52 Carbon Steel LSAW Pipe Origin of Material

Suppliers and stockist of API 5L X52 LSAW Pipe

Buy API 5L X52 LSAW Pipes in Stock at cheap prices

API 5L X52 LSAW Pipe- information about the pipe for buyers

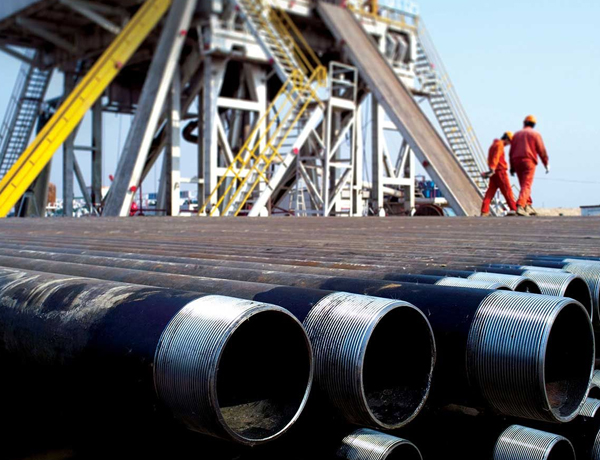

So you are looking to buy the API 5L X52 LSAW Pipe are welded stainless steel pipes for gas and oil. Its outer diameter is 406 to 1524mm. The wall thickness of the pipe is 8mm to 30mm. Its length is 3m to 12 mm and also according to the requirements of clients. The standard specifications of pipes are API 5L, JIS3444, ASTM A53, EN10255, BS1387, AS1074, and JIS3452. The pipes are manufactured by those manufactures that are legally certified under BV, SGS, CCIC, ISO 9001:2008 and many more.

The available finishes of pipes are black paint on its surface, oil on its surface and bare pipe and galvanized pipe. The pipe ends are like bevel end, threaded on two ends, plain end, one end with coupling and one end with the plastic cap. The pipes supplying is done as per the requirements of clients or the mill standard. The technical terms used for API 5L X52 LSAW Pipe is SAW. Trade term used while trading is FCA, FOB, EXW, CFR, and CIF.

Packaging-

The packaging of the pipe is not done if less 273mm. The loose packaging of pipes is done and piece by piece. The API 5L X52 LSAW Pipe is packed in wooden or cartoon boxes or as per the demand or requirements of customers. The packaging is done much carefully to prevent the pipes from corrosion and damages. When the pipes are supplied, the supplier takes full guarantee of replacing and refunding if clients are not satisfied with the product or have found the damaged product.