API 5L X56 PSL2 FBE Coated Pipes, API Steel Grade X56 PSL2 Pipes, IBR approved 3LPP Coated API 5L X56 PSL2 Pipe, API 5L L390 PSL2 Steel Pipe Stockists, Carbon steel API 5L X56 PSL2 Welded Pipe Supplier, API 5L X56 PSL2 Line Pipe Exporter in Mumbai, India.

3LPE Coating API 5L L390 PSL2 LASW Pipe Dealers in Mumbai, X56 PSL2 Sour Service Pipes Stockholders, API X56 PSL2 Semaless Line Pipe in India, API 5L L390 PSL2 Carbon Steel DSAW Pipe Traders, Black Steel API 5L X56 PSL2 ERW Pipe Distributors.

Table of Content

API 5L X56 PSL2 Pipe seamless and welded pipes

API 5L X56 PSL2 Pipes Specifications

API 5L L390 PSL2 Steel Pipe Chemical Composition

API 5L Grade X56 PSL2 Pipes Mechanical Properties

Carbon Steel API 5L X56 PSL2 Pipe Origin of Material

Suppliers, Exporter of API 5L X56 PSL2 Pipe

Buy API 5L X56 PSL2 Pipes in Stock at cheap prices

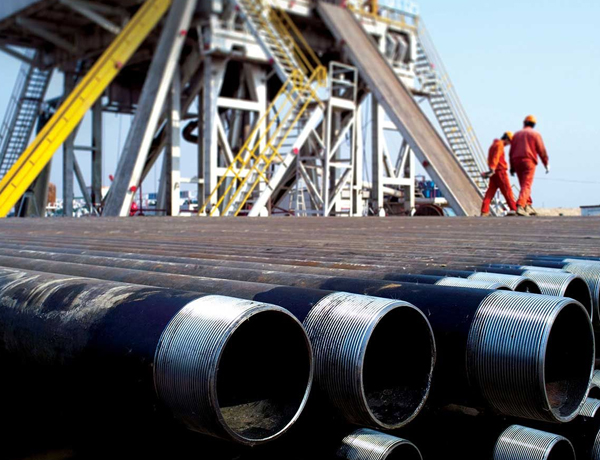

API 5L X56 PSL2 Pipe seamless and welded pipes

Both welded steel line and seamless pipes are covered under API 5L X56 PSL2 Pipe. Majorly, they are manufactured to be used in pipeline transportation system but they hold importance in other areas as well. Although these pipes are available in various size ranges and the size range is primarily restricted on purposes basis and manufacturer's capabilities. International organization for standardization standardizes the specification for materials that are used in pipeline transportation system. Manufacturers, thus adhere to these standards while manufacturing the pipes. PSL 1 and 2 are the basic product specifications level for these pipes.

PSL 1 defines specifications for their quality whereas PSL 2 defines specifications for the mechanical and chemical properties along with the testing requirements. The specifications cover various grades for these pipes where X56 is one among those. Various Suppliers supply stocks of API 5L X56 PSL2 Pipe seamless pipes that are as per the international and national standards in terms of quality, packing, certification and more.

Other details:

API 5L X56 PSL2 Pipe should undergo various testing such as IBR, NACE mR0175, NACE TM0284, SSC TEST, HIC TEST, H2 SERVICE, NACE TM0177 and more. They should be inspected as per the relevant standards specified for them to ensure their quality and safety. Exporters or suppliers should ensure that their products offer high tensile, high strength and heavy wall line pipe requirements that are essential to use the pipes in various environments. This carbon steel pipe should pass the various certification and traceability test before they reach to the consumers. Moreover, they should contain the specified percentage of elements to attain the desired strength and durability.